RF Over Fiber (RoF or RFoF) is a technique used in communication systems to transmit radio frequency signals over an fiber optic network. Current radio frequency transmission is typically done with copper coaxial cabling. Benefits of migrating communication systems to fiber are well known including increased data rates, bandwidth and security over the network. Applications in telecommunications include wireless transmission, cable TV and satellite ground stations. In the military/aerospace sector RoF is being implemented in systems such as radar and electronic warfare.

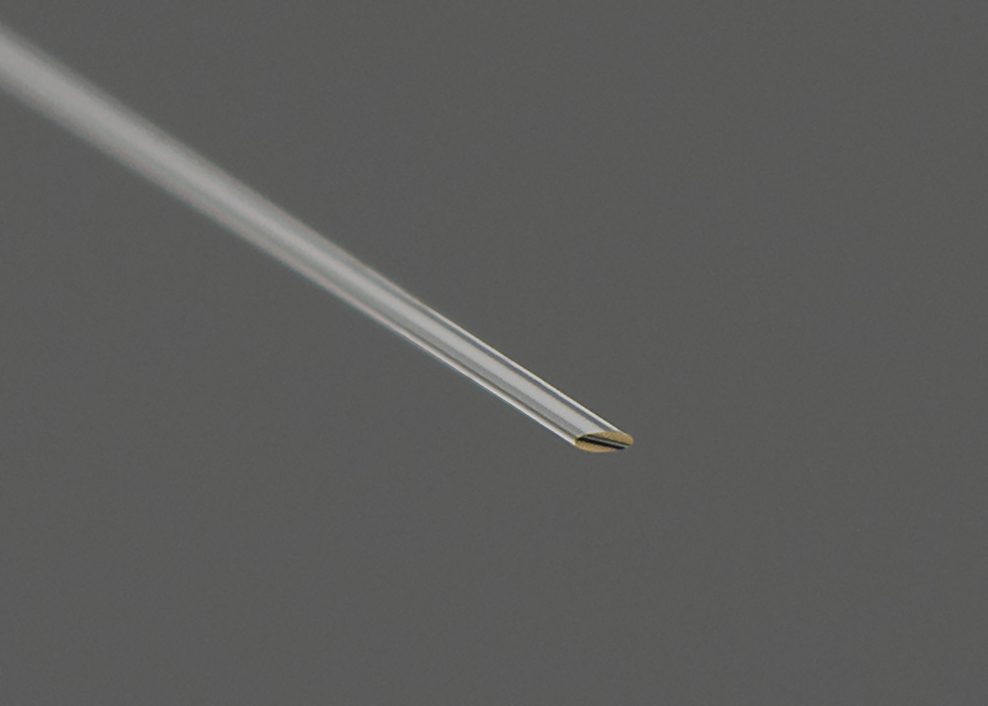

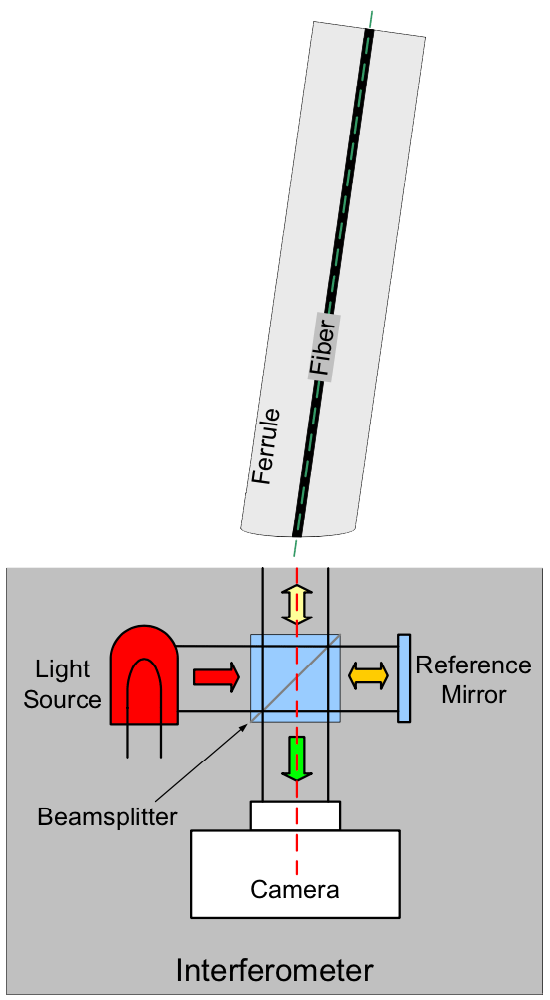

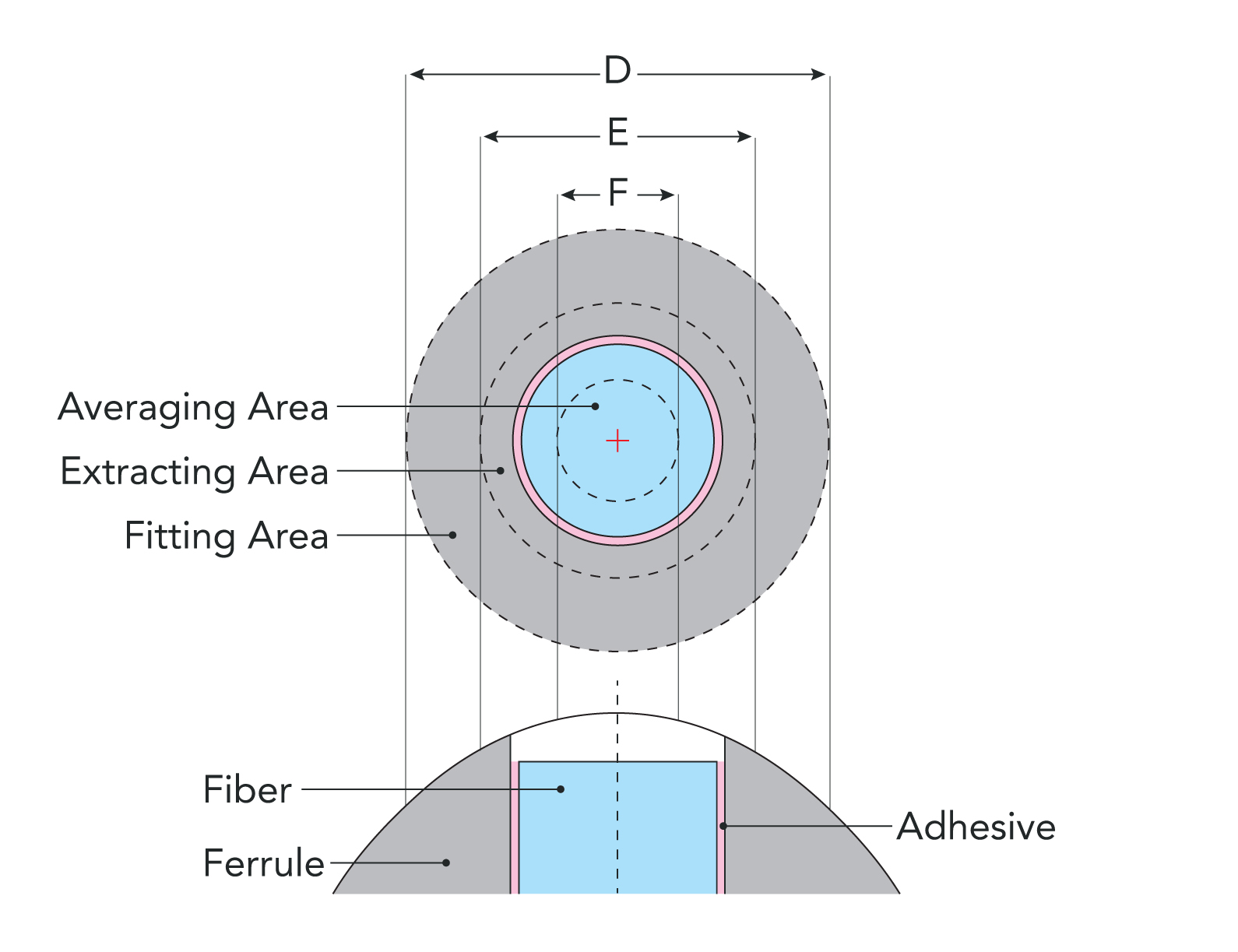

At the present time, the bandwidth requirements for new RoF systems dictate that single mode (SM) fiber be utilized in the network implementation. Because SM, with it’s 9 um core, requires precise alignment between connections, ensuring the proper connection geometry is essential.

RoF typically utilizes a intensity modulation method requiring high power laser pulses. Because of the high laser powers involved in conjuncture with SM fiber; cleanliness, core alignment, and proper polish are essential for proper system function.

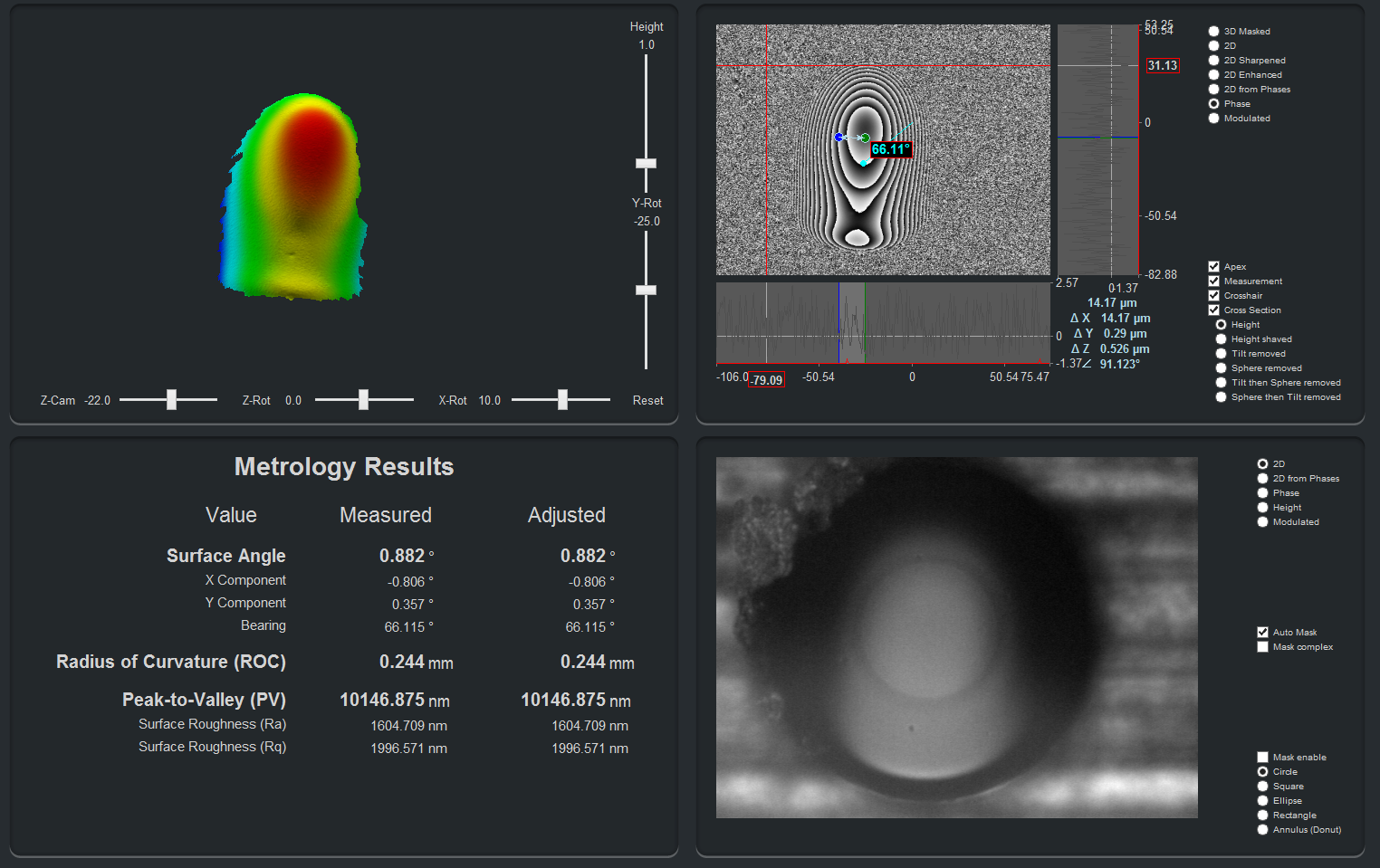

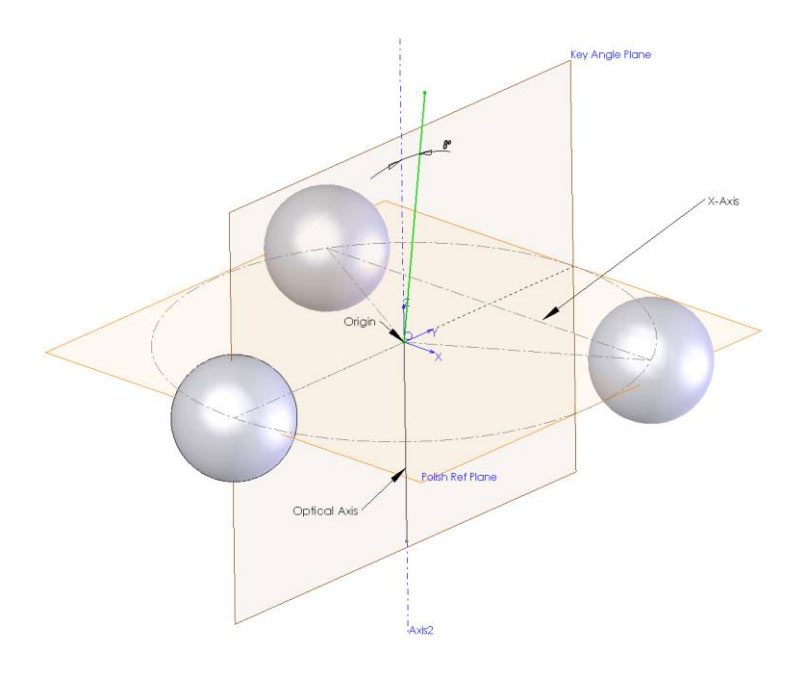

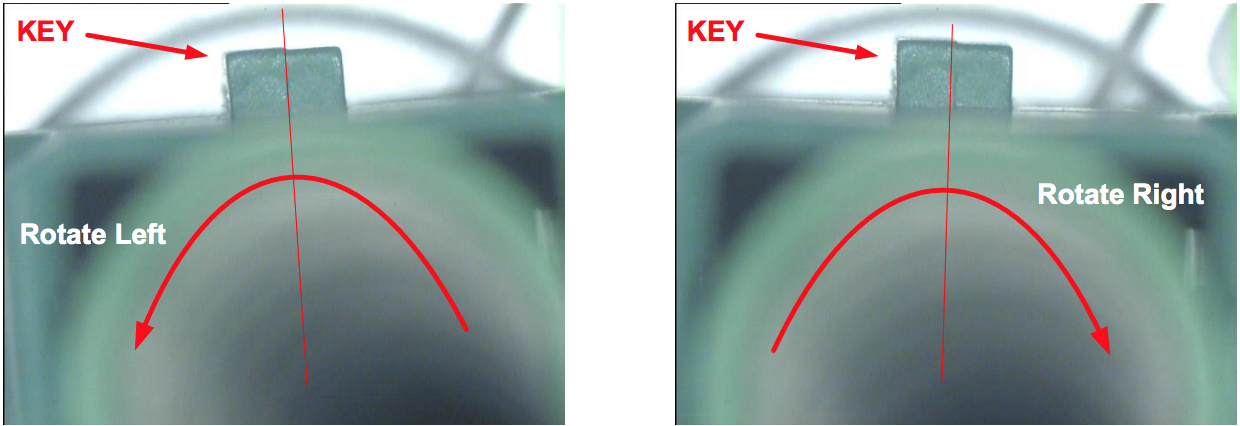

Due to the high laser powers involved in RoF compared to normal communication systems, issues that would normally only cause poor performance may actually cause damage to the system. Back reflections, for example, into the laser source can cause the laser to behave undesirably or worse, damage the laser diode itself. This problem does have a simple and common solution in the form of APC polishes.

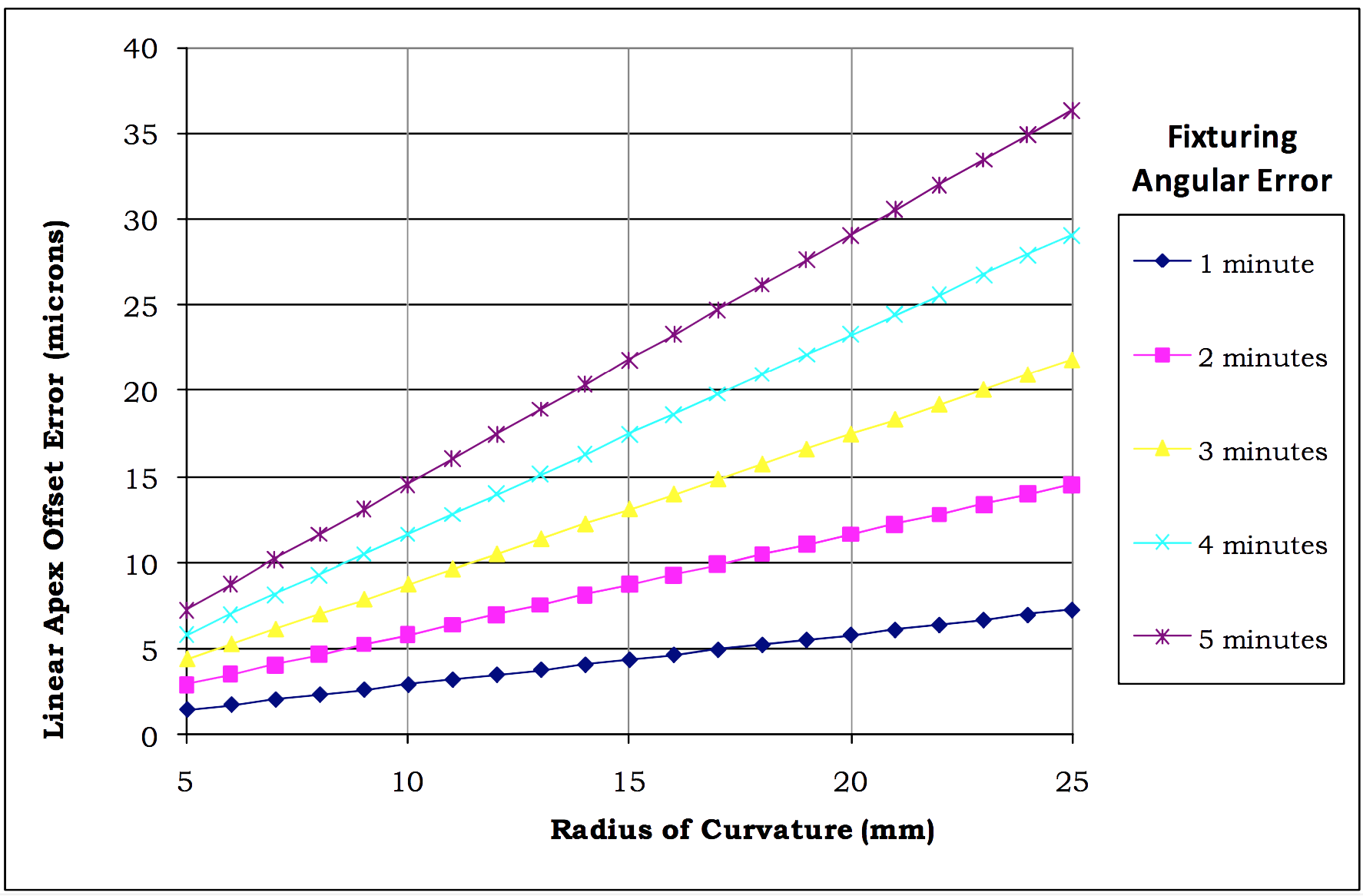

Excess Apex Offset will result in loss of signal propagating through to the next fiber core but can also result in laser ablation of the fiber endface leaving pits that allow scattering and further fiber degradation. Poor polish and particles on the endface can have a similar effect. Hence, with any type of fiber system, cleanliness is essential.

RoF is an application that will continue to be employed in the world around us. Endface geometry inspection on fiber connections is a controllable step to to ensure proper system function and continued system health.

Special thanks to Max Lemire, Northeastern Electronics; formerly Lockheed Martin; experience with Mil/Aero fiber systems since 1986, for his contributions to this post.