MIL SPEC Termini

MIL style termini connections are extensively used in a variety of harsh environment applications such as aerospace, defense, oil & gas and back bone telecom. These connections make it possible to use of a variety of connectors from the circular 38999 to rectangular modular connectors like the EPX and everything in between. Endface inspection of each termination is especially important for these connection styles due their use in mission critical communication and sensor systems. Such systems are continuously exposed to temperature cycling, repeated mating and other harsh environmental factors. While endface inspection is typically done in the controlled environment of a manufacturing facility, field terminations are common in many aerospace/defense platforms requiring a portable interferometer system, such as FiBO.

Applications

- 1.25 mm ferrule

- Ex. ARINC 801

- 1.6 mm ferrule

- Ex. M29504/4 & /5

- 2.0 mm ferrule

- Ex. M29504/14 & /15

- 2.5 mm ferrule

- Ex. EN4531

Important Features

- Compliance with MIL-STD-1678, SAE AS-5675 (JELI) measurement standards

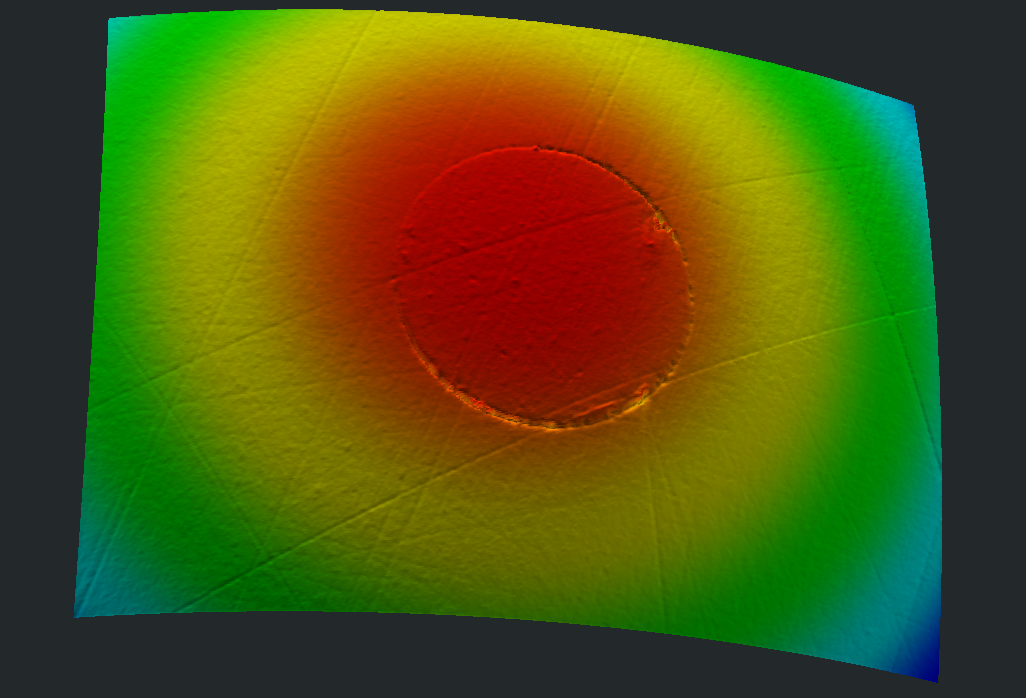

- Radius of curvature, fiber height and apex offset measurement

- Automatic pass/fail surface defect analysis

- Measurement history database

- Customizable endface measurement standards

- Surface roughness

- ISO/NIST traceable calibration

- Quick change magnetic kinematic adapters

- Rugged carrying case

- Portable, light weight & small form factor