Flat Polish

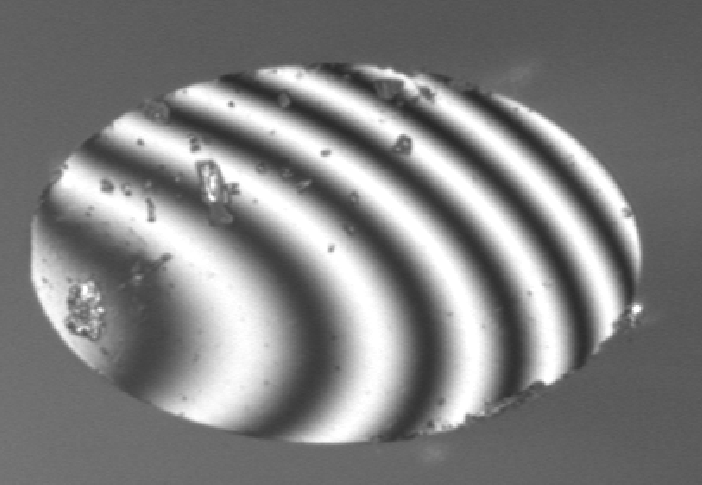

Flat polishing is used in a variety of applications for connectors/termini and bare fibers. The surface flatness can be easily inferred utilizing standard 125 µm fiber fringe counting, assuming a 0° tilt of the fiber endface. However, actual endface tilt angles can vary depending on both the polish of the fiber itself and the fixture in which it is held. Measuring this tilt angle is especially important for flat polished connectors, as performance of the connection is dependent on acceptable tilt values in each connector.

Cleaved bare fibers can be flat polished after cleaving, requiring a combination measurement of cleave angle and surface flatness.

Applications

- Standard connectors & termini

- SMA

- R & D

- Mechanical cleaves

- Laser cleaves

- 8° cleaves

- 0-50° cleaves

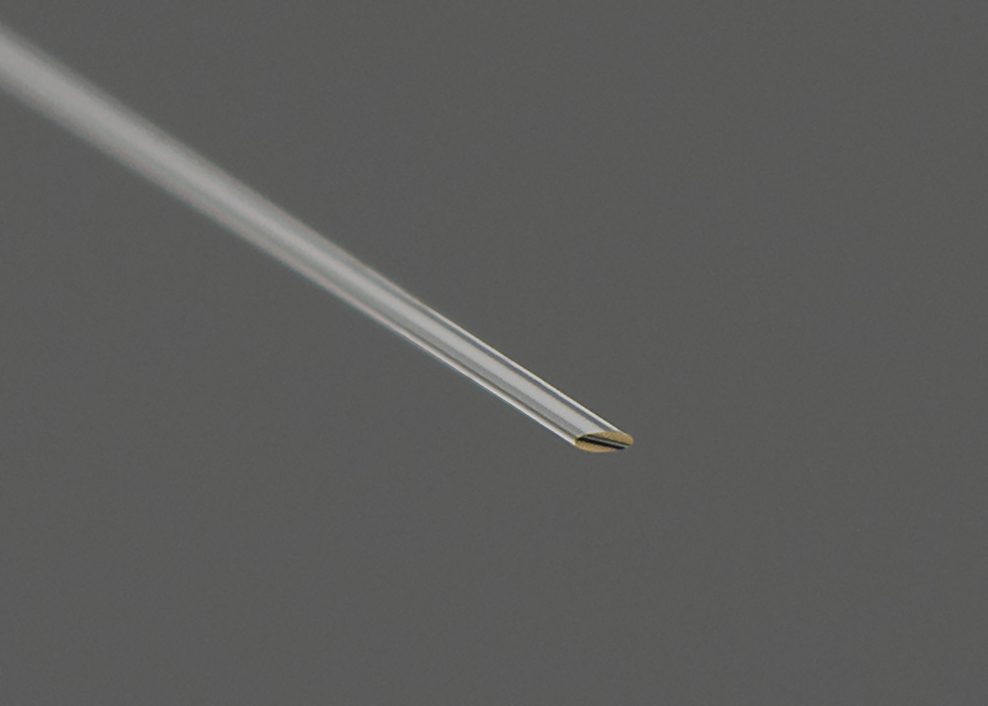

- 70 – 1500 µm diameter fibers

System Features

- Cleave angle measurement

- Measure up to 7° tilt

- X-Y cleave angle components

- 3D endface surface geometry

- .csv measurement history database

- Feature masking

- 2D X-Y surface profile

- Software angle adjustment to match VATS angle

- Adjustable Field of View (FOV)

- 3.4x 1000 µm x 800 µm

- 10x 360 µm x 270 µm

- 20x 200 µm x 150 µm