Optical fiber is cleaved for a variety of reasons like splicing or direct bonding. In some applications it is critical to measure the angle at which the fiber was cleaved at. The most common being 0 degrees or 8 degrees, corresponding to the common PC & APC connection standards.

This video walks through how to measure the cleave angle of a bare fiber using the FiBO 300. Further discussion of how to measure bare fiber is below.

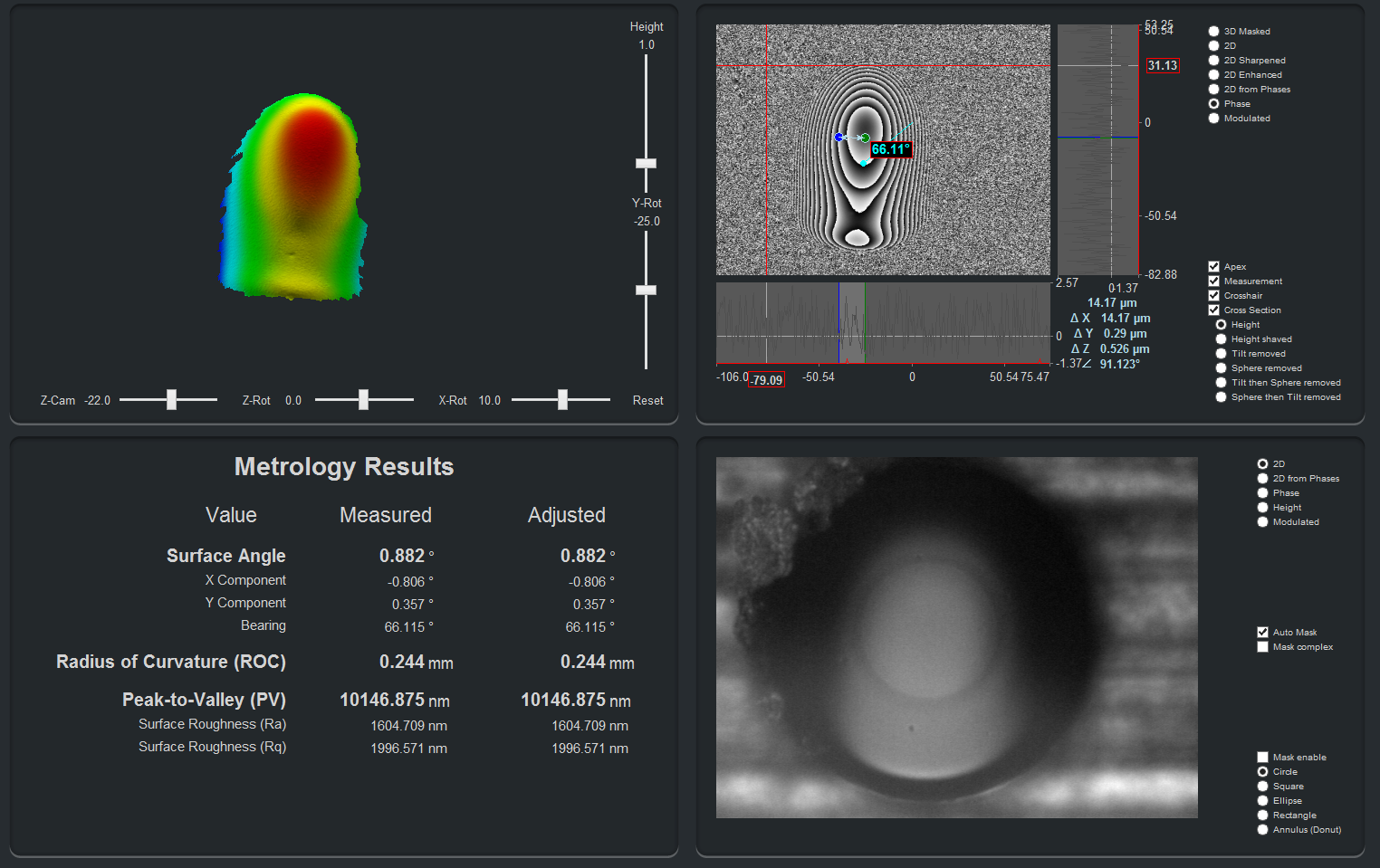

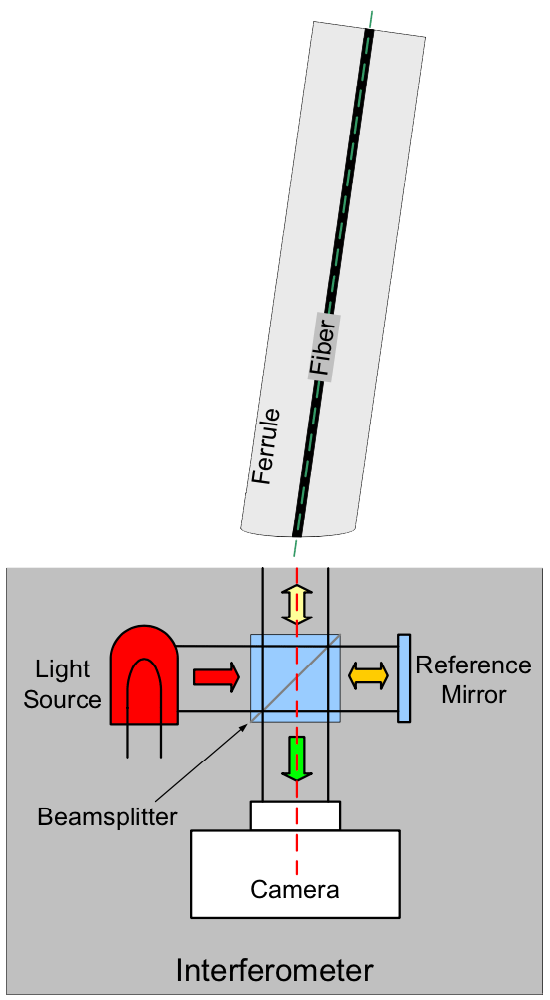

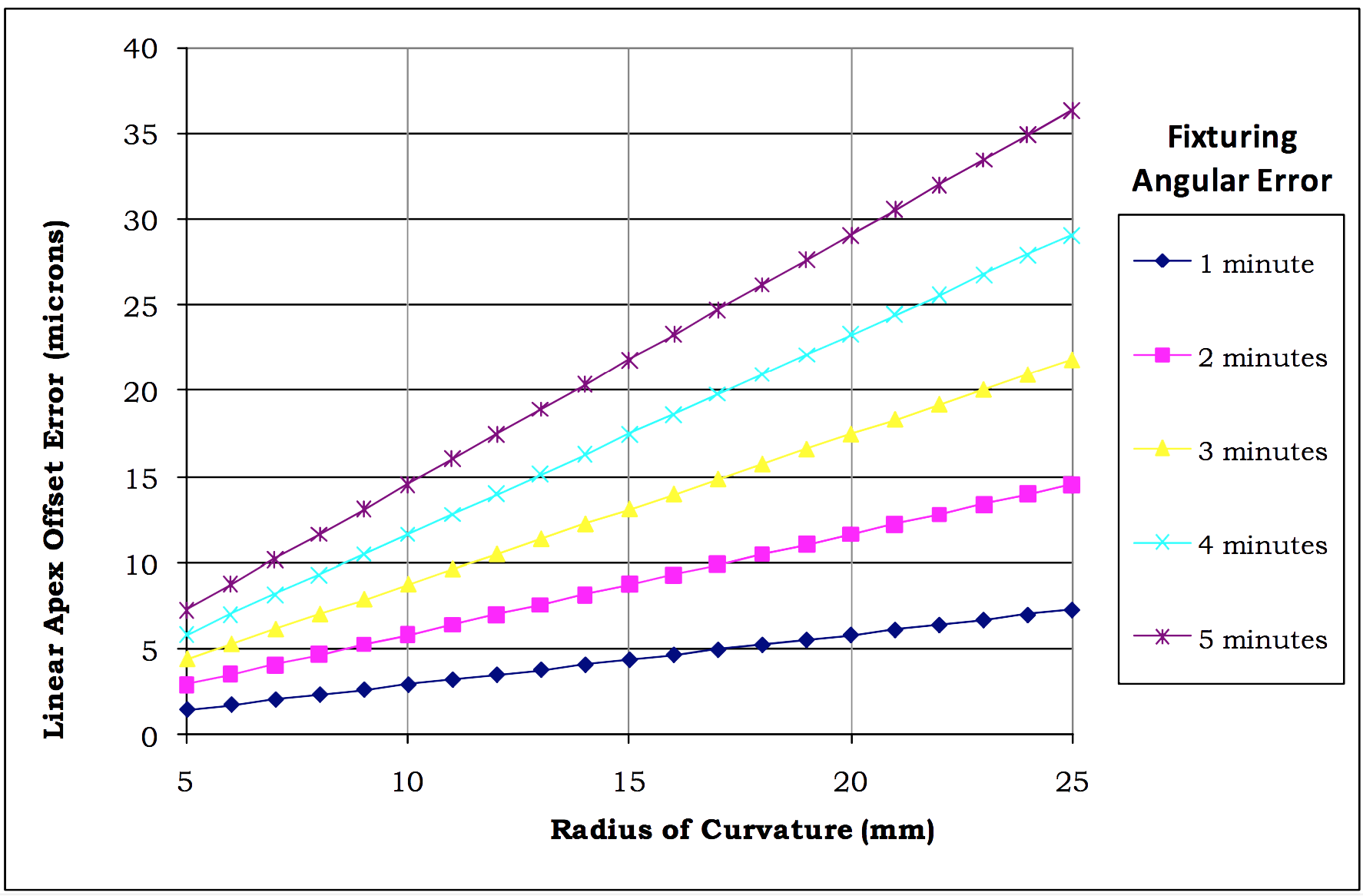

Interferometric endface inspection to measure cleave angle has been used for many years. However, there are a few challenges facing engineers and technicians for accurate measurements. The most significant is that without the mechanical references and rigidity provided by a connector body, the tip of a bare fiber is very difficult to align in a manner that will allow an accurate measurement of the cleave angle.

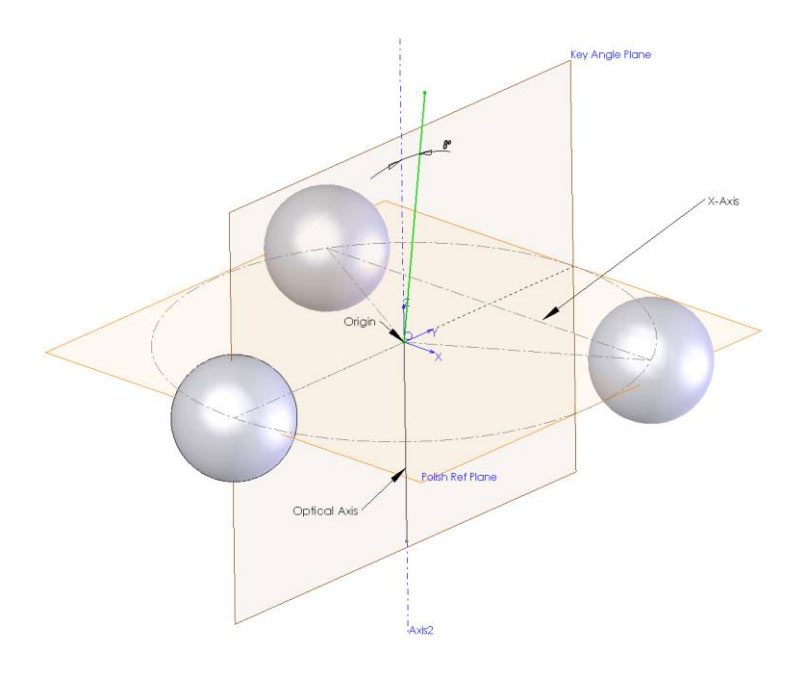

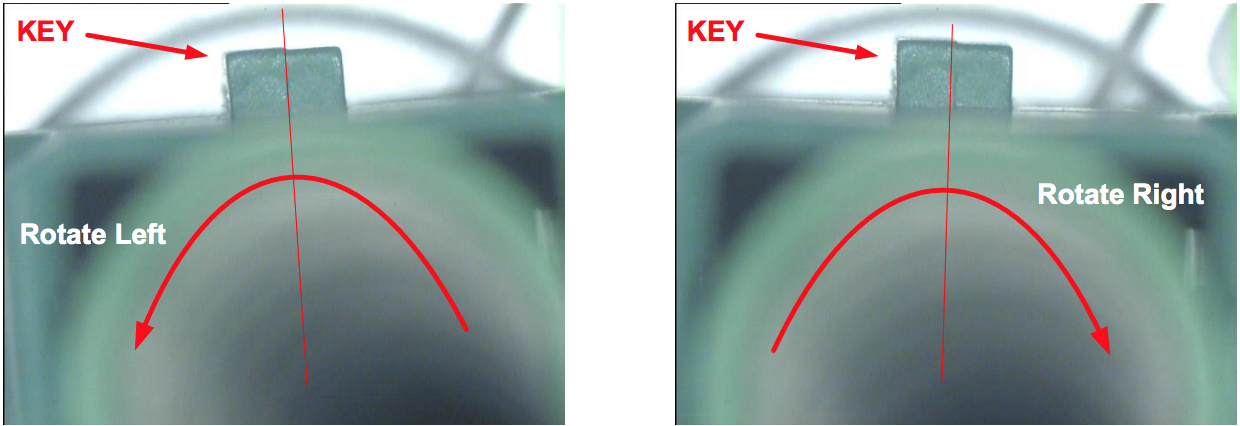

Promet Optics, as a precision opto-mechanical design and manufacturing company, tackled these issues by designing fixturing that mate to the optically aligned kinematic interface of the FiBO Interferometer. The goal of the fixturing design was to eliminate angular error and tilt of the fiber to be measured in reference to the optical axis of the instrument. This alignment is critical for accurate cleave angle measurements.

From a user’s perspective the most difficult part of inspecting a bare fiber is positioning the bare fiber properly in the direction parallel to the fiber (z direction), such that the tip of the fiber is sitting in, and perpendicular to, the focal plane of the instrument. Normally, the connector body provides the instrument and the user a mechanical reference to ensure proper positioning. To solve this problem, Promet Optics designed a v-groove Bare Fiber Chuck (BFC), that provides a defined position for the tip of the fiber to be, as well as rigidity to the fiber itself. Knowing where the fiber tip is located in space is essential to focus on it. This BFC mates to a 3.2 mm PC or APC adapter, to make a repeatable and well defined reference interface from which the cleave angle measurement is taken from.