Laser cleaving is still a relatively new technology in which a laser is used instead of a mechanical blade to cleave fibers before polishing. The benefits of laser cleaving include a more reliable cleave process as well as a significant reduction or elimination of time required for subsequent polishing procedures. This process can be applied to single fibers, ribbon fibers, specialty connectors and waveguides. Despite the relative novelty of laser cleaving, it is already rapidly expanding into the manufacturing of MTP and other multifiber connectors.

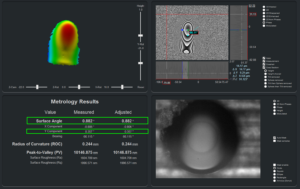

The ability to shape the endface of the cleaved fibers for a specific application is another benefit of laser over mechanical cleaving. Accurate inspection of these resulting endface geometries requires an interferometer or other 3D surface profiling method. Utilizing existing interferometer systems for fiber optic connectors is the easiest solution.

Typical parameters of interest to R&D and production personnel inspecting laser cleaves:

1.) Overall cleave angle

Fibers are typically cleaved at a specified angle, so the cleave angle is a measure of the deviation from the desired angle.

2.) X-Y components of the cleave angle

X-Y components indicate the orientation of the fiber during the cleave. For single fibers this is important in situations where a feature is rotationally oriented in reference to the cleave direction. For ribbon fibers the cleave is typically perpendicular to the array of fibers, thus the Y component should ideally be 0 deg for a normal ribbon fiber cleave.

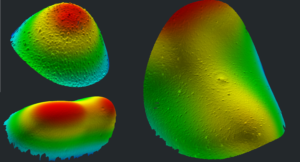

3.) Shape of the cleave

The shape of the cleave is important for a proper polish as well as a clear understanding of the optical performance. Acceptable endface shapes are typically defined for a specific application or laser cleaver configuration.

These and other values are then used to develop the necessary process parameters.

Single fiber cleaves can be inspected using a number of products on the market. However, multifiber interferometers used to measure MTP and MPO connectors are configured to measure the entire fiber array in accordance with industry standards as a single “connector”. In order to measure individual fibers in a ribbon fiber, unique accessories are neccessary to allow for the endface geometry inspection of individual cleaves in a ribbon. Specialized fixturing for the FIBO Interferometer, such as the Fiber Ribbon Stage, allows a ribbon to be taken directly from the laser cleaver and inspected without removing it from the ribbon holder. Likewise, inspection can be done on MT ferrules and other specialty multifiber connectors.