Non-Contact Surface Profile

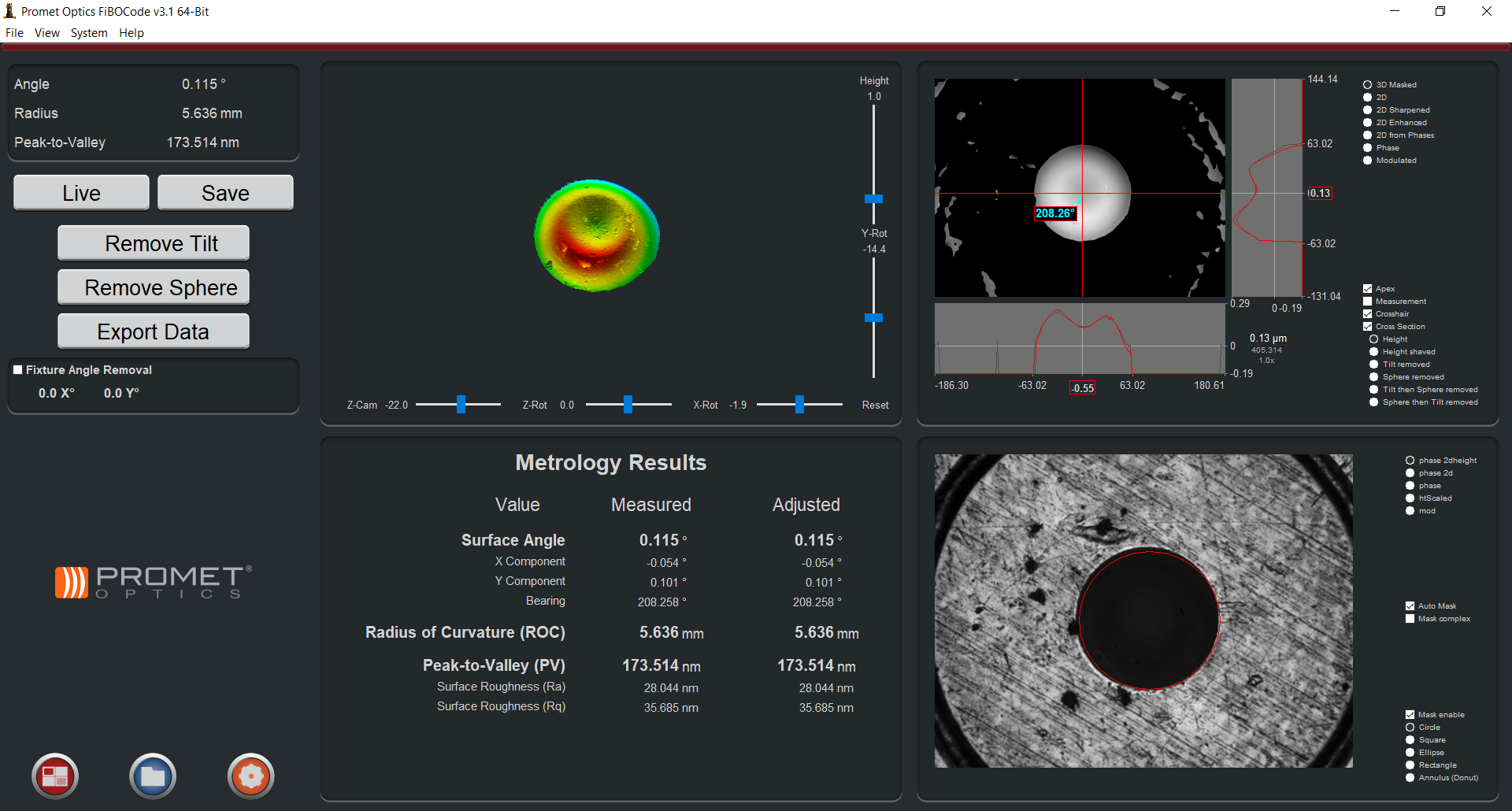

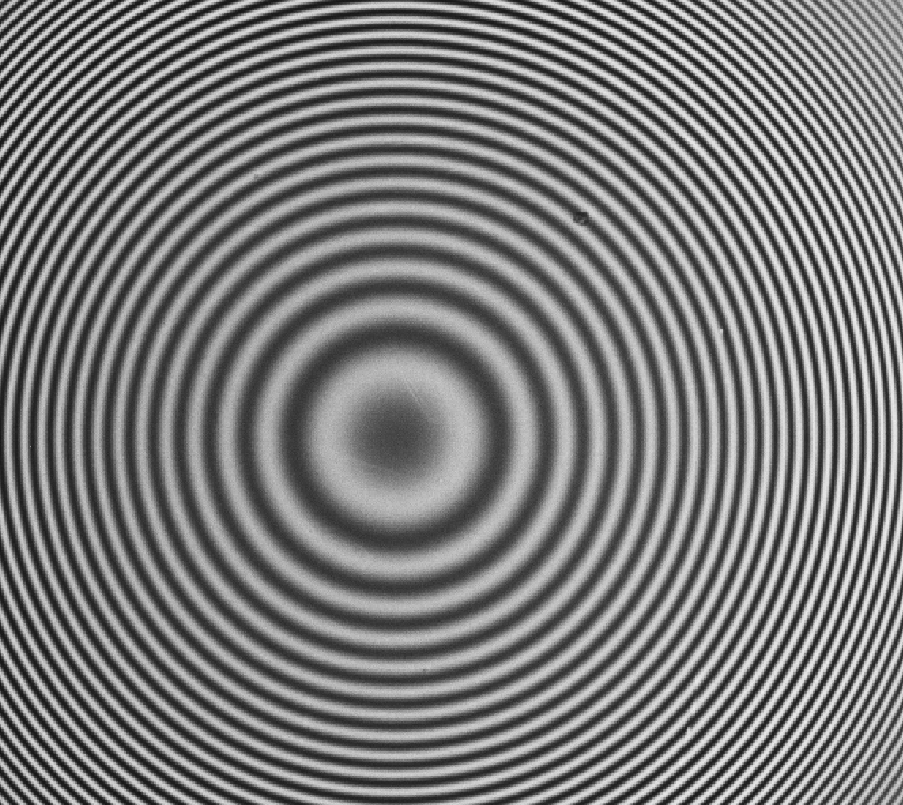

Interferometers are widely used for non-contact, nanometer resolution, surface profile measurements in the optics industry. Interferometers utilizing LED light sources for several hundred µm fields of view (FOV) were developed specifically for inspecting the endface geometry of fiber optic connector endfaces. This type of interferometer is also capable of taking surface profile measurements of any surface that can be imaged in the FOV. The FiBO 300 model was designed with multiple FOV options, which allow for the measurement of large diameter fibers, fiber endcaps, micro optics, etc.

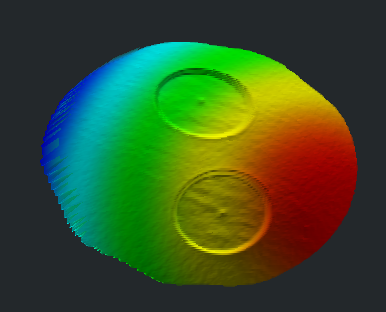

Many new types of fiber with assorted structures or features inside the fibers require measurement of surface geometry as well as analysis of the fiber features. Software tools like 2D side profiles, distance measurements between features, and angular measurements between features have been incorporated into FiBO Code software for just these applications.

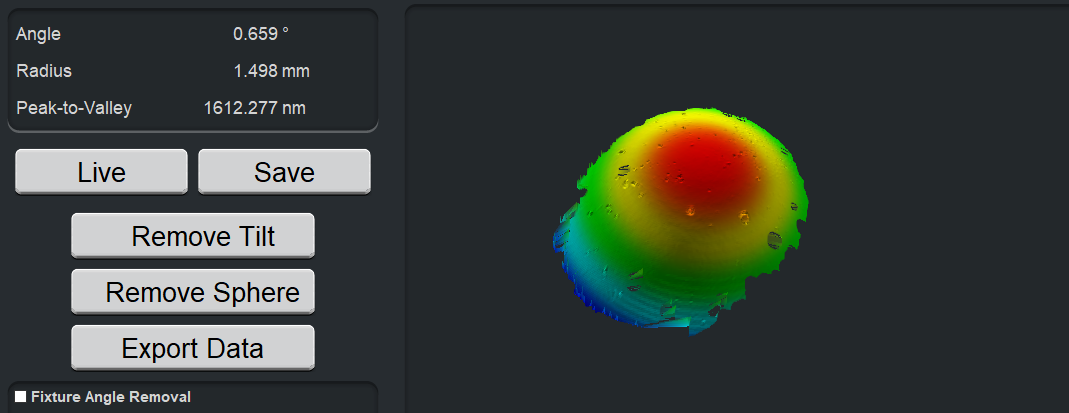

As electronics become smaller, corresponding optical systems are also getting smaller. The FiBO 300 takes radius and flatness measurements of micro optics, <20 µm radius, with areas of interest smaller than 1 mm.

Applications

- Specialty fiber structures

- Ex. stress rods, hollow core PM

- Specialty polished fiber

- Fiber endcaps

- Micro-optics

- Ball lenses

Important Features

- Exportable non-contact surface geometry

- Cleave angle measurement

- X-Y cleave angle components

- Feature masking

- X-Y-Z between feature measurements

- Angle between feature measurements

- Radius measurement

- .csv measurement history database

- 2D X-Y surface profile

- Specialty fixtures

- Adjustable Field of View (FOV)

- 3.4x 1000 µm x 800 µm

- 10x 360 µm x 270 µm

- 20x 200 µm x 150 µm