Laser Cleaved Ribbons

Ribbon fibers are increasingly being used for applications where a high physical channel density is required. These ribbon fibers can be connected utilizing a standard connector such as MTP, a specialized interconnect, direct bonding or other specialty methods.

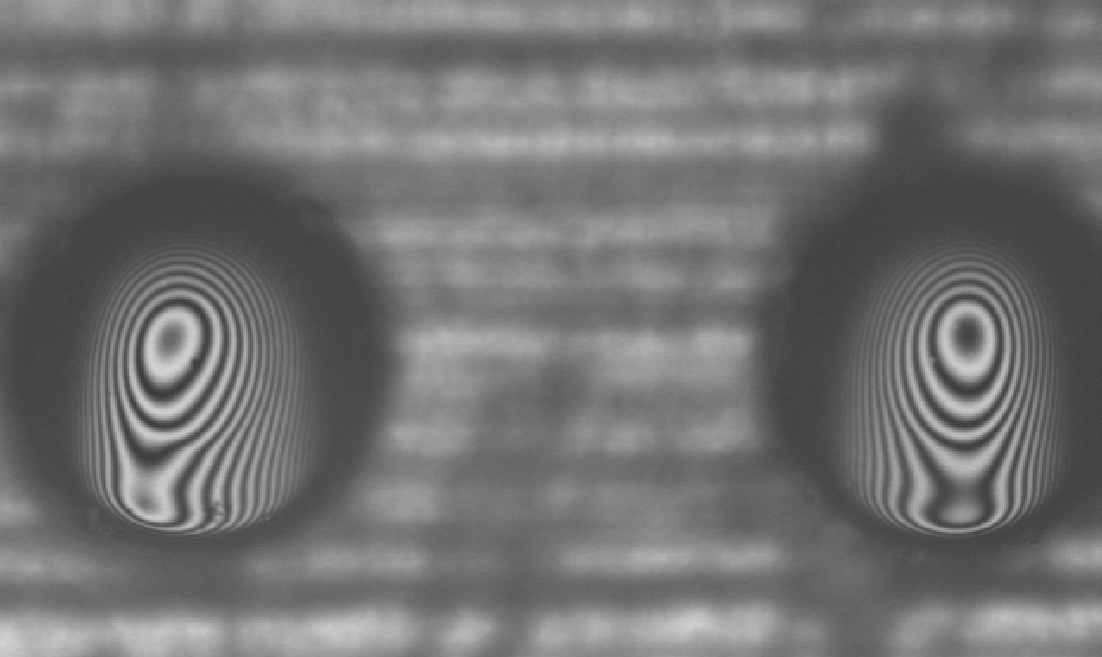

Laser cleaving is a relatively new method of fiber cleaving that is quickly being adapted into the manufacturing processes for ribbon fiber applications. Here a laser is used instead of a mechanical blade to cleave fibers before polishing. Among the benefits of laser cleaving is a significant reduction or elimination of time required for polishing as well as an ability to actively shape the fiber endface.

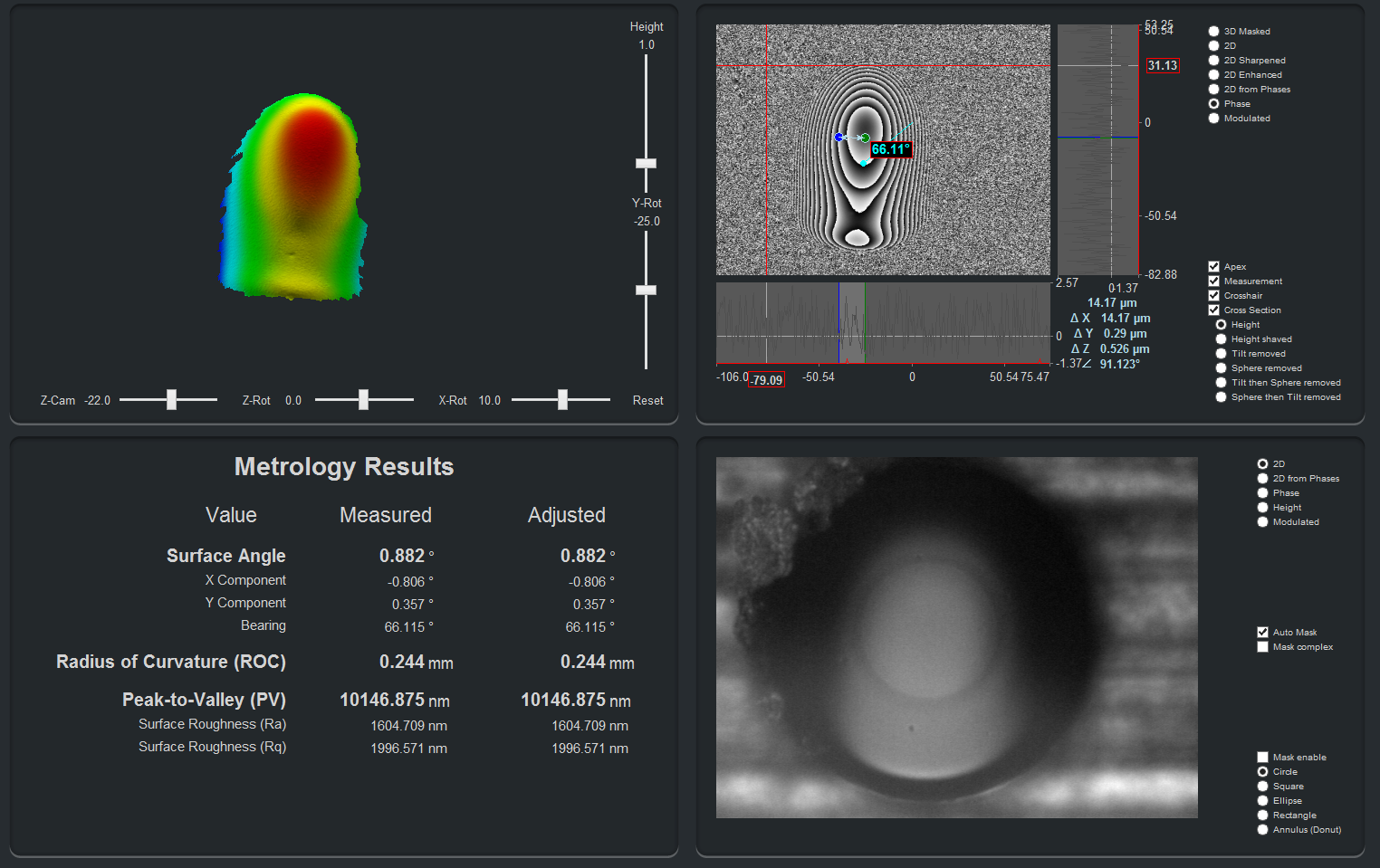

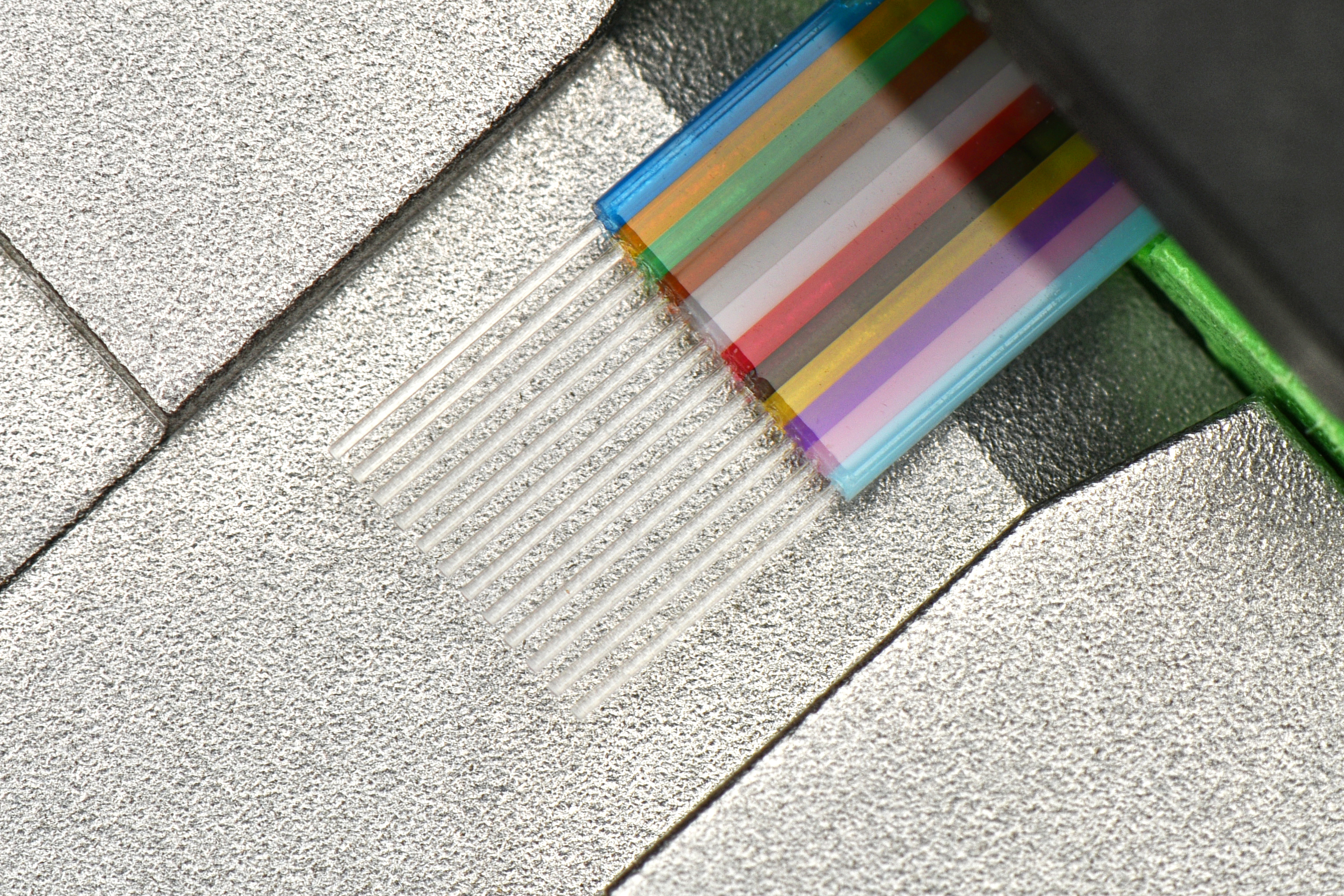

Interferometric endface inspection has been used for single fiber mechanical cleaves for years. Applying this metrology to use with ribbon fibers simply requires fixturing, such as the Fiber Ribbon Stage which allows scanning through individual fibers in a ribbon, one at a time.

Applications

- MTP ferrule

- Specialty multifiber interconnects

- Specialty optoelectronic interconnects

- Cleave angles 0-15°

- Laser cleave process validation

- QC inspection and documentation

System Features

- Cleave angle measurement

- X-Y cleave angle components

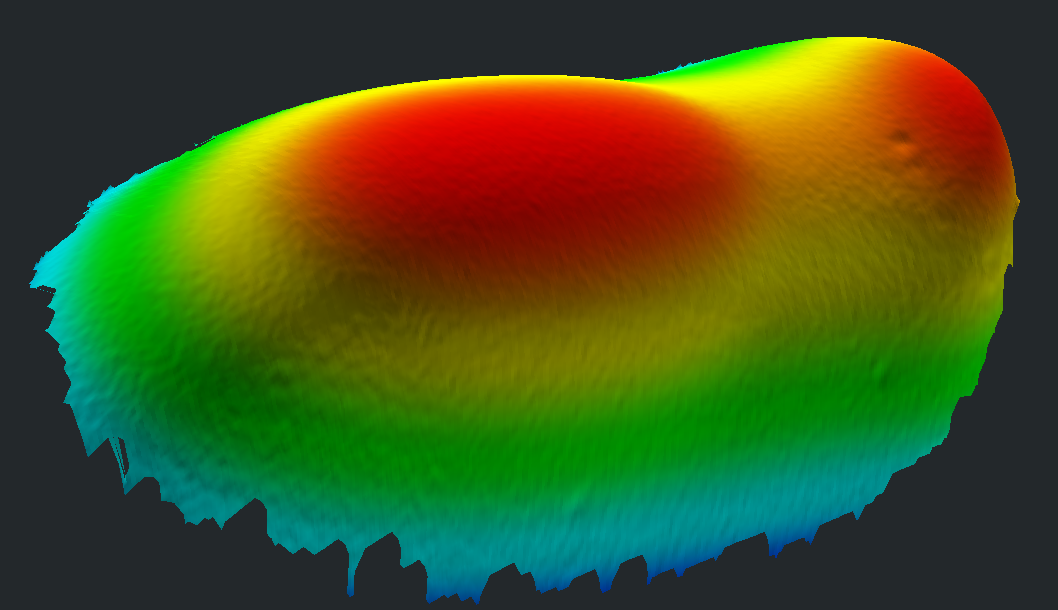

- 3D endface surface geometry

- Radius fitted to surface measurement

- .csv measurement history database

- Feature masking

- 2D X-Y surface profile

- Standard & custom connector fixtures

- Cleave holder fixtures

- Up to 4 row, 64 fiber fixtures

- Adjustable Field of View (FOV)

- 3.4x 1000 µm x 800 µm

- 10x 360 µm x 270 µm

- 20x 200 µm x 150 µm